In the industrial equipment, forklifts are one of the most important machines that make material handling possible. Central to the operation of the forklift is the forklift hydraulic pump. But isn’t it time we ask ourselves whether that performance is constant?

Durable Materials to Ensure Reliability

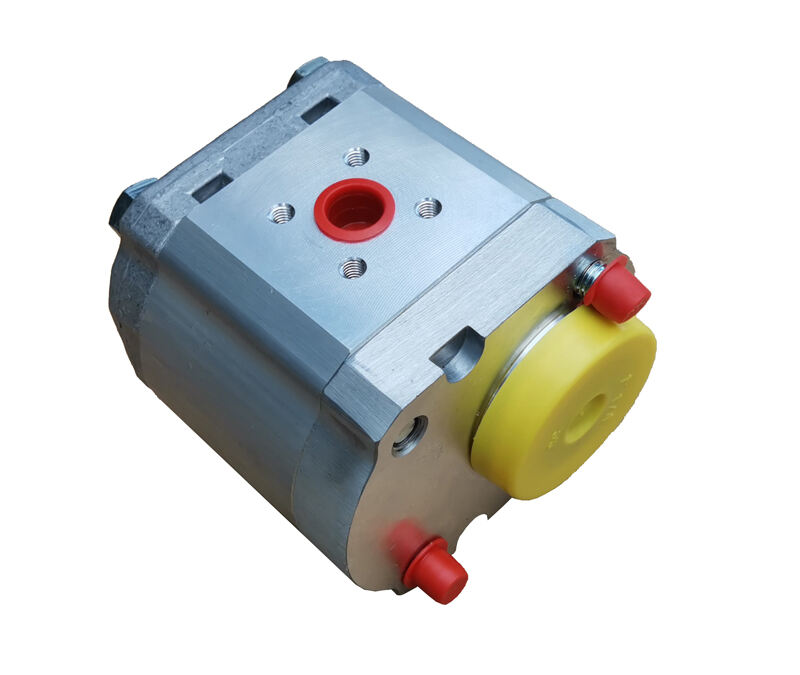

The accessories of the forklift hydraulic pump are made from durable materials. So that they are able to stand the test of time. From hard wearing metals to synthetic polymers, almost all parts of the hydraulic pump are made able to endure heavy industry usage and provide dependable operation over a period of time.

Perfect design is necessary

Stability of the forklift hydraulic pump also depends on its design and engineering. By combining state of the art manufacturing processes and quality control, the pump is designed to operate effectively and yield little variation. The pump designed for use and specifically large ones portrays a number of advanced technologies such as computer oriented design and simulation.

Scheduled Maintenance for Steady Usage of the Equipment

It cannot be argued against the fact that in order to achieve stable functioning of the hydraulic pump of a forklift, adequate maintenance would be needed. Maintenance activities like cleaning, inspection and lubrication can be done to the pump to ensure that performance issues are addressed before they impact the performance of the pump. If proper operational and maintenance practices are followed, using the manufacturer’s recommended replacements and the fluids improves the performance of the pump and longevity as well.

In summary, it is evident that stable performance can be expected from the hydraulic pump of the forklift due to the use of engineering plastics, proper designs, and consistent upkeep. This is one of the most important elements that ensures maximum optimization and efficiency of the fork-lift operations and safety in factories and worksites.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

HY

HY

AZ

AZ

ONLINE

ONLINE